INSTALLATION INSTRUCTIONS

Commercial Room Ventilator with ExhaustModel: CHCRV-5For Use with Bard C**H Series 3, 4 & 5 Ton2-Stage Wall Mount Heat PumpsandW38H, W43H, W49H & W61HT36H, T42H, T48H & T60HT36S, T42S, T48S & T60S C36H, C42H, C48H & C60HSingle Stage Wall Mount Heat Pumps

Bard Manufacturing Company, Inc.Bryan, Ohio 43506www.bardhvac.com

Manual: 2100-450MSupersedes: 2100-450LDate: 3-1-21

GENERAL

GENERAL INFORMATION

The ventilator should only be installed by a trained heating and air conditioning technician. These instructions serve as a guide to the technician installing the ventilator package. They are not intended as a step-by-step procedure with which the mechanically inclined owner can install the package.

The ventilator housing is shipped in one carton which contains the electrical harness, miscellaneous hardware, and installation instructions.

UNPACKING

Upon receipt of the equipment be sure to compare the model number found on the shipping label with the accessory identification information on the ordering and shipping document to verify that the correct accessory has been shipped.

Inspect the carton housing of each ventilator as it is received, and before signing the freight bill, verify that all items have been received and that there is no visible damage. Note any shortages or damage on all copies of the freight bill. The receiving party must contact the last carrier immediately, preferably in writing, requesting inspection by the carrier’s agent. Concealed damage not discovered until after loading must be reported to the carrier within 15 days of its receipt.

DESCRIPTION

The CHCRV-5 ventilator is designed to be used with Bard CH Series; Bard W38H, W43H, W49H, and W61H Series; Bard T36H, T42H, T48H, and T60H Series; Bard T36S, T42S, T48S, and T60S Series; Bard C36H, C42H, C48H, and C60H Series 3 through 5-ton wall mount series heat pumps. They are electromechanical vent systems designed to provide fresh air to meet indoor air quality standards.

MODELS:

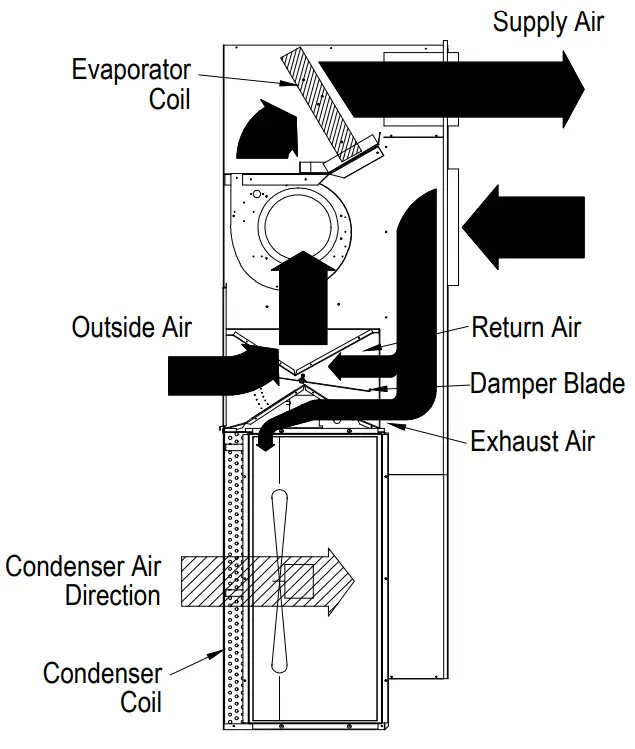

When installed in the above-listed models, the CRV provides built-in exhaust provisions. When the damper blade opens to bring fresh air in, the damper also opens an exhaust relief. The exhaust air will flow into the condenser section of the unit. The condenser fan will help draw exhaust air out when it is operating with the compressor in cooling or heat pump mode.

INSTALLATION

BASIC INSTALLATION

- Unpack the ventilator assembly which includes the integral ventilator with attached electrical harness and miscellaneous hardware.

- Remove and save the existing exterior blower access, filter access, and service access panels on the Bard wall mount unit. (See Figure 1.)

- Remove and save existing unit air filter and screws from the front center grille. (See Figure 1.)

WARNINGOpen and lock unit disconnect switch before installing this accessory to prevent injury or death due to electrical shock or contact with moving parts. Turn the thermostat off.

MODEL FOR USE WITH THE FOLLOWING UNITS CHCRV-5 W38H W43H W4911/VV61H T3611 T42 H T4811/T6011 T36S T42S T48S/T6OS C36H C4211 C48H/C6OH - Remove and discard back CRV exhaust cover platefor W38-61H, T36-60H & T36-T60S models. Remove front CRV exhaust cover plate on C3660H models.

- Install ventilator by inserting the ventilator into the unit to the far left side clearing the right filter bracket. Once the ventilator is fully inserted, slide the ventilator to the right until it is tight against the back of the control panel. (See Figure 2.)

FIGURE 1REMOVAL OF EXTERIOR PANELS, AIR FILTER, AND EXHAUST COVER PLATE

IMPORTANT: Position the front lip of the ventilator on top of the front grille and condenser partition. (See Figure 2 inset.) This is important to ensure proper drainage of any water entering the damper assembly.

- Open control panel to gain access to unit low voltage terminal block.

- Route electrical harness leads through the 7/8″ bushings in the control panel (See Figure 2) into a low voltage box.

-

Install the vent control board in the upper left corner of the control panel. Route the pink, purple, and black wires through the upper grommet.

FIGURE 2INSTALL VENTILATOR

-

Connect a purple wire from CHCRV to P terminal on vent control. Connect a pink wire from CHCRV to P1 on vent control. Connect the black wire from CHCRV to C on vent control. Connect an orange wire from CHCRV to 01 terminal on the unit low voltage terminal block. Connect the black wire from vent control to C terminal on low voltage terminal strip. Connect a purple wire from vent control to Y1 terminal on a low voltage terminal strip. Connect yellow wire from vent control to Y terminal on low voltage terminal strip. Connect the red wire from vent control to R on the low voltage terminal strip.

- Close control panel cover

- Replace left filter support, filter, and four (4) screws in the condenser grille.

- Reinstall the blower access panel at top of the unit and secure it with sheet metal screws.

- Ventilator CheckoutA. Resupply power to the unit.B. Energize the evaporator blower by switching the thermostat to the manual fan position with heat/ cool in OFF position.C. Ventilator should open to the position set by#1 Potentiometer on vent control. Cycle position adjustment thumbwheel to full open through full close. Observe damper blade operation throughout travel to assure free,unobstructed movement.D. De-energize evaporator blower. The damper blade should close.E. This completes ventilator checkout.

- Replace mist eliminator. Be sure it is installed with the drain holes to the bottom.

- Remove blank off the plate or barometric fresh air damper installed on the service access door. Plug four (4) mounting holes with the plastic plugs provided with the ventilator.

- Replace the service access panel.

- A ventilator is now ready for operation.

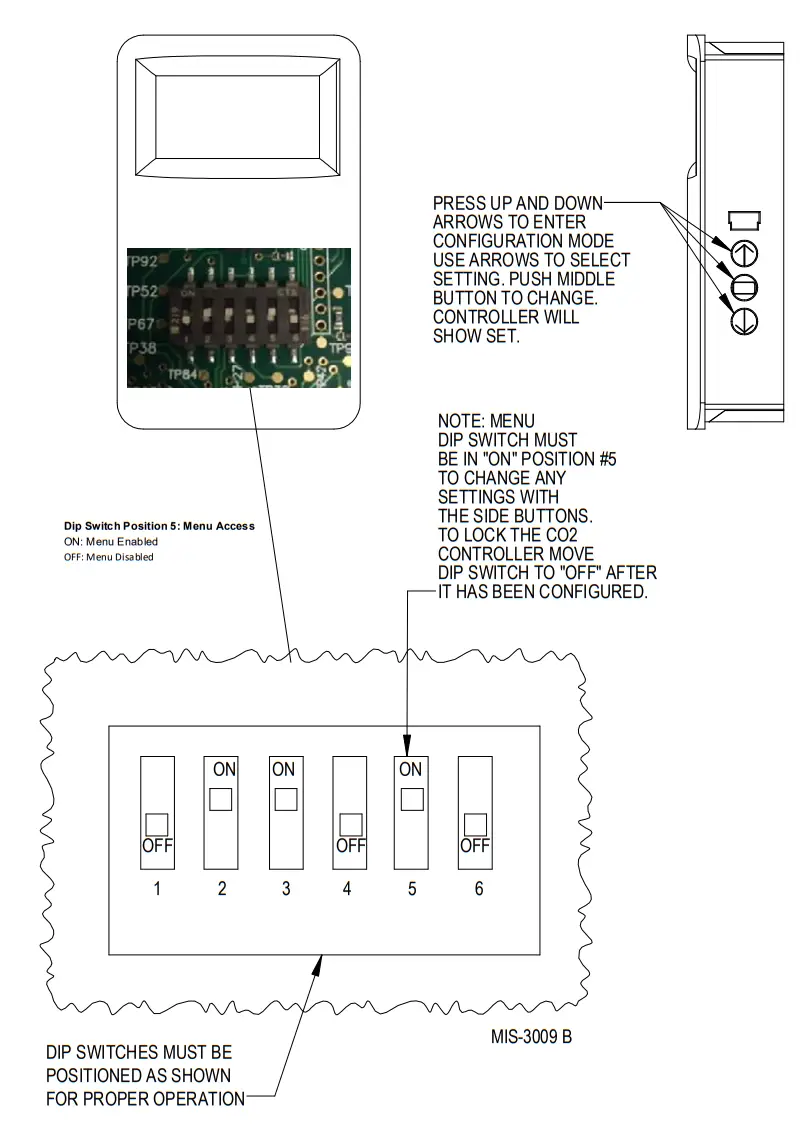

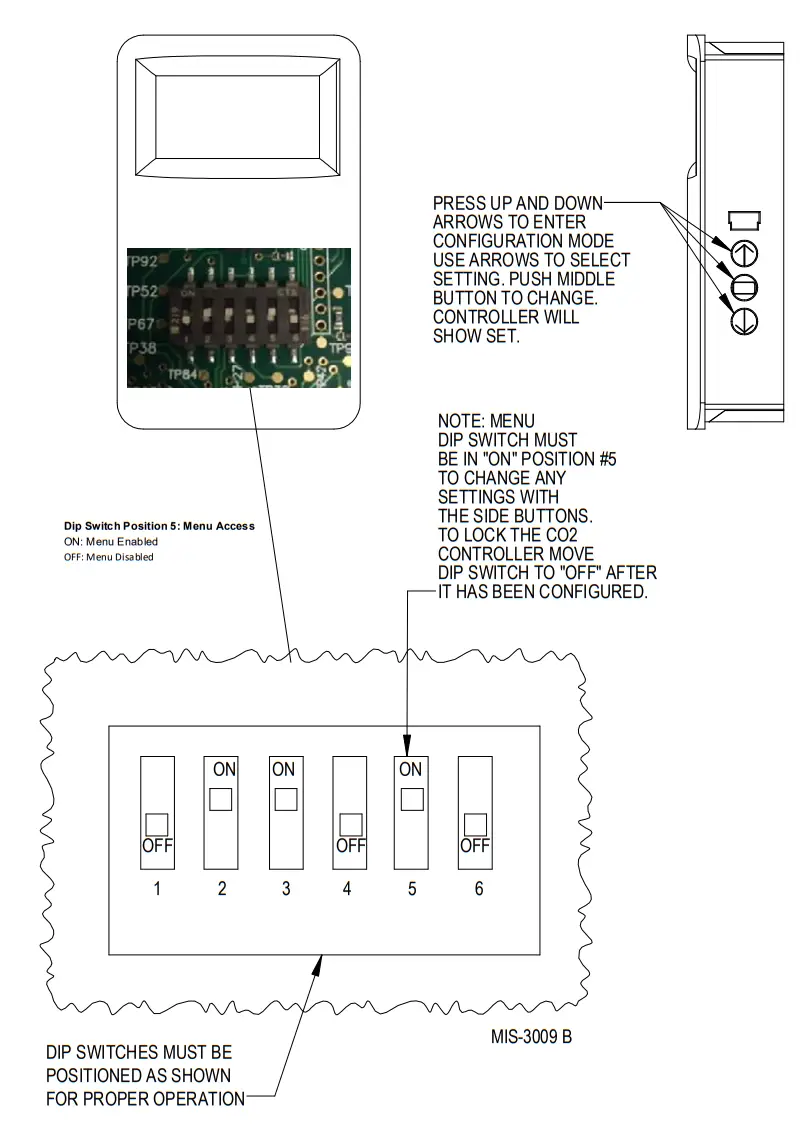

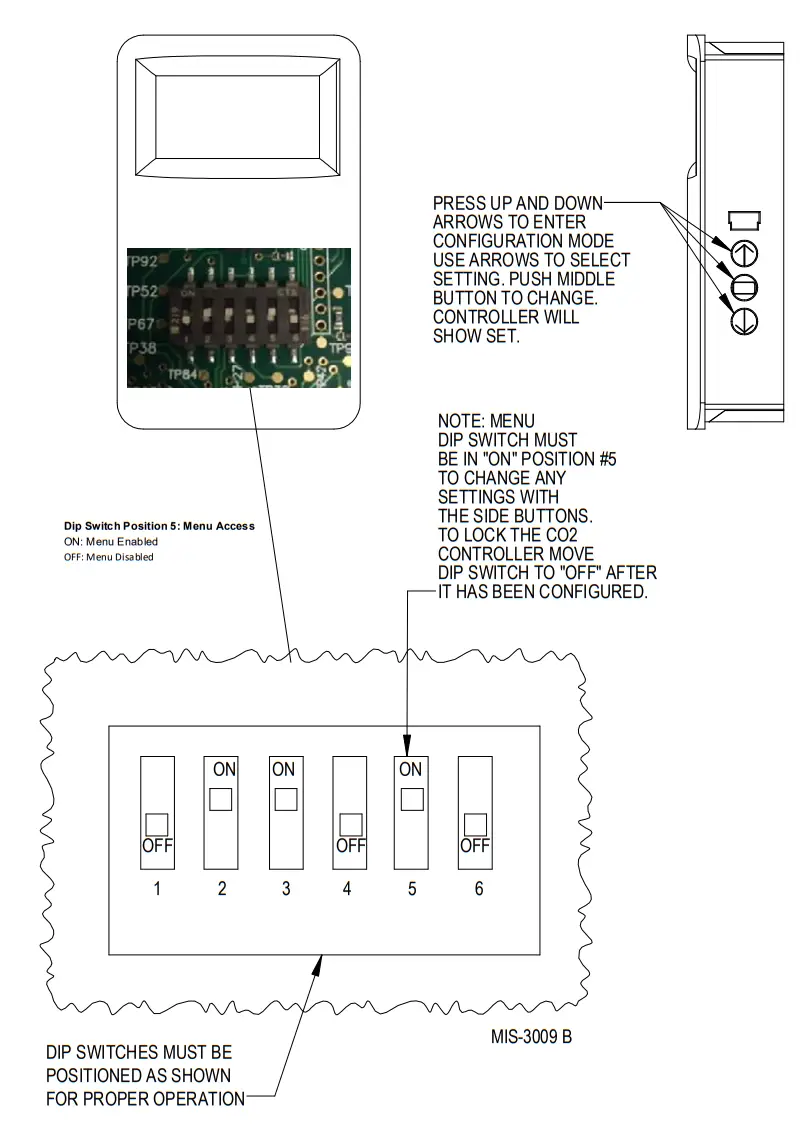

CO2 CONTROL

For CO2 -based control, add a CO2 sensor/controller (Bard Part #8403-096) to the wall and run additional optional wires as shown in Wiring Diagrams.4056-207 for W38H, W43H, W49H, W61H, and T**H Series. 4056-187 for the T**S or C**H Series.

The CO2 controller also must be re-configured from the standard default settings as it comes out of the box. See the next two pages for complete details.

FIGURES 3 & 4CO2 SENSOR DEFAULT & FINAL SETTINGS 8403-096 CO2 CONTROLLER

- The damper should be fully closed at 700 ppm, if not Potentiometer R7 can be adjusted clockwise (CW) to close it. If it is fully closed at 700 ppm or lower no adjustments are required.

- Blade as referenced to the Blade Position Label.

| Settings | Recommended | Default |

| RON | Not Used | |

| ROF | Not Used | |

| DSP | C | CT |

| UNI | US | US |

| COL | 700 | 0 |

| COH | 1500 | 2000 |

| TOL | Not Used | |

| TOH | Not Used | |

| BAR | See Instruction with Controller For High Altitude Installations | |

| CAL | Used for Field Calibration |

| 4-20mA | AN (ppm) | Damper (1) | Approcrositi Blade , Position (2) |

| 4 | 700 | FULLY CLOSED | 0 |

| 5 | 750 | 1 | |

| 6 | 800 | 2 | |

| 7 | 850 | 3 | |

| 8 | 900 | 4 | |

| 9 | 950 | 5 | |

| 10 | 1000 | 6 | |

| 11 | 1050 | 7 | |

| 12 | 1100 | 8 | |

| 13 | 1150 | 9 | |

| 14 | 1200 | 10 | |

| 15 | 1250 | 11 | |

| 16 | 1300 | 12 | |

| 17 | 1350 | 14 | |

| 18 | 1400 | 15 | |

| 19 | 1450 | 16 | |

| 20 | 1500 | FULLY OPEN | 17 |

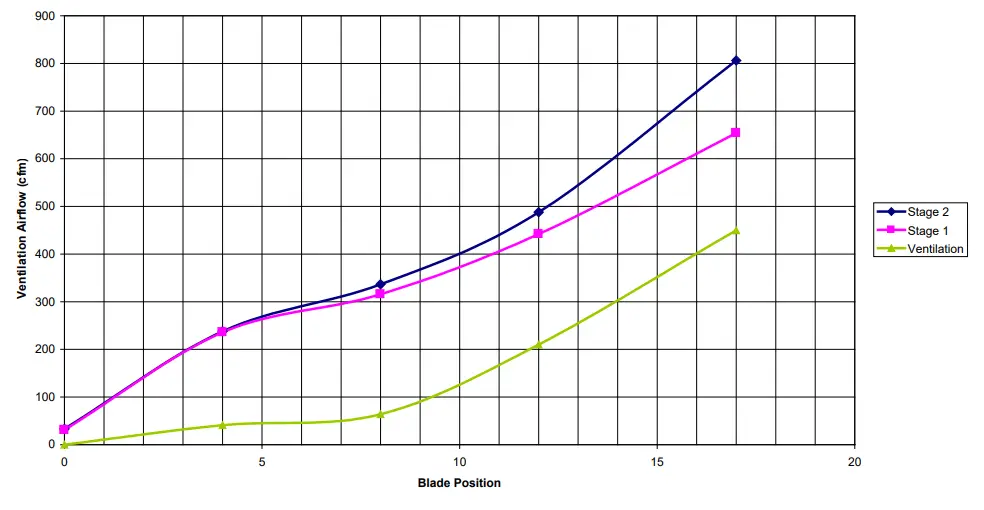

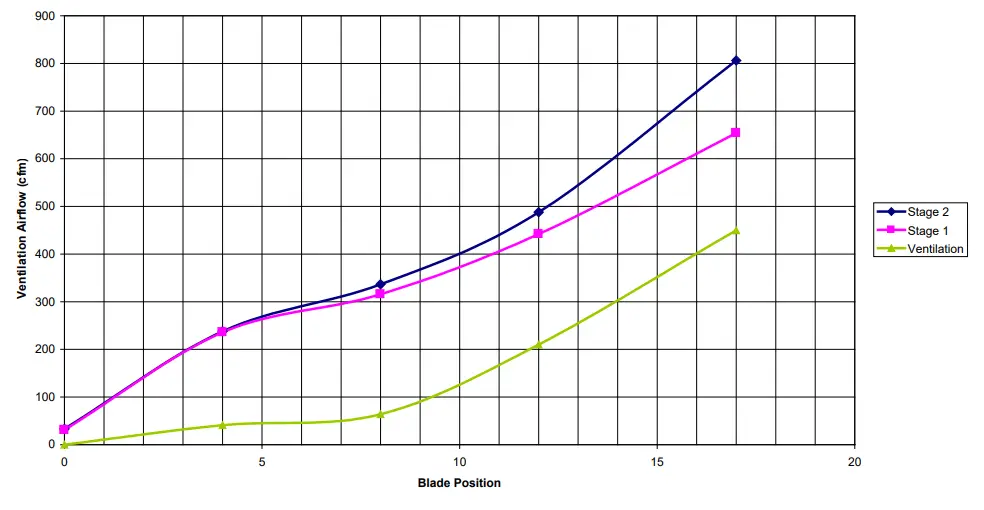

BLADE ADJUSTMENT FOR DESIRED VENTILATOR AIR

The amount of ventilation air supplied by thecommercial room ventilator is dependant on four (4)factors.

- Return air duct static pressure drop.

- Supply air duct static pressure drop.

- Indoor blower motor speed.

- Damper blade open position setting.

Refer to the graph below to determine the blade setting necessary to achieve the ventilation air required for each operating mode.

| C**H | T**H | |

| T**S | W**H | |

| Potentiometer R1. | 17 | 17 |

| Potentiometer R2. | 14 | 14 |

| Potentiometer R3. | NA | NA |

For more accurate adjustment, use a flow hood over the intake opening to measure and adjust the airflow operation.

Potentiometer R1. Adjusts the airflow during blower operation only.Potentiometer R2. Adjusts the airflow during 1st stage of cooling or heating operation.Potentiometer R3. Adjusts the airflow during 2nd stage of cooling or heating operation.

Energize blower only mode and adjust #1Potentiometer to the desired airflow.

Energize 1st stage cooling mode and adjust #2Potentiometer to the desired airflow.

Energize 2nd stage cooling mode and adjust #3Potentiometer to the desired airflow.

Minimum damper position when using CO2 control damper should be fully closed at 700 ppm or lower, if not Potentiometer R7 can be adjusted clockwise (CW) to close it. If it is fully closed at 700 ppm or lower, no adjustments are required.

GRAPH 1CH3S1 Vent Airflow C36H, C42H & W38H1 VENT AIRFLOW

GRAPH 1CH3S1 Vent Airflow C36H, C42H & W38H1 VENT AIRFLOW

GRAPH 3C60H VENT AIRFLOW CH5S1 Vent Airflow

GRAPH 4

COMMERCIAL ROOM VENTILATOR – CH SERIES

FEATURES

- One-piece construction – Easy to install with no mechanical linkage adjustment is required.

- Exhaust air damper – built-in with the positive closed position. Provides exhaust air capability to prevent pressurization of tight buildings.

- Actuator motor – 24 volt, power open, spring return with built-in torque-limiting switch.

COMMERCIAL ROOM VENTILATOR SEQUENCE OF OPERATION

On a call for blower operation, CRV opens to a position as set by #1 Potentiometer. See Figure 5.

NOTE: These sequence descriptions do not apply if a CO2 controller is used. The CRV will control according to observed CO2 levels in the conditioned space. Refer to information on Page 7.

FIGURE 5CALL FOR VENTILATION WITH OR WITHOUT COMPRESSOR OPERATION

MIS-1944 A

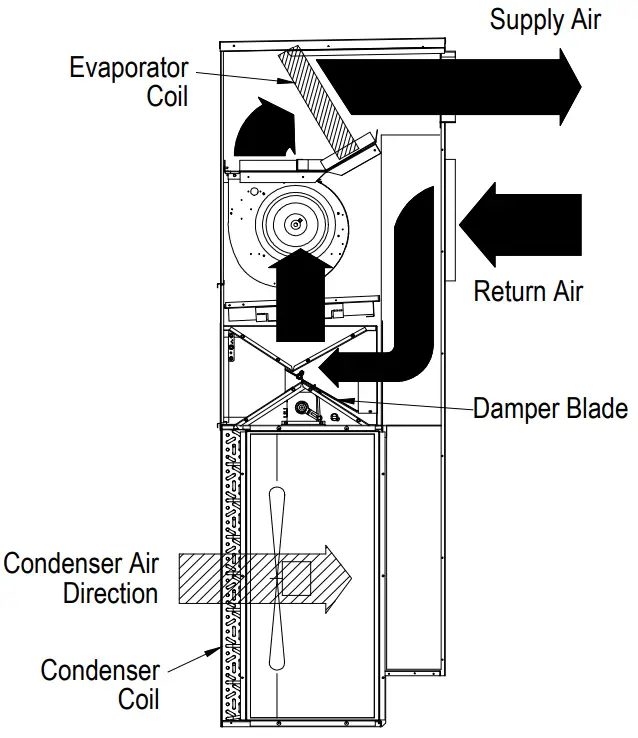

A call for 1st stage cooling or heating cycles the compressor, and the dampers reposition to the Potentiometer #2 setpoint. A call for 2nd stage cooling or heating energizes compressor solenoid and repositions the damper blade to the Potentiometer #3 position. On loss of blower operation, CRV closes fully. See Figure 6.

FIGURE 6CALL FOR COMPRESSOR OR FAN ONLY WITH VENTILATION OFF

MIS-2031 A

COMMERCIAL ROOM VENTILATOR – W38, W43 W49 & W61H MODELS

FEATURES

- One-piece construction – easy to install with no mechanical linkage adjustment is required.

- Exhaust air damper – built-in with the positive closed position. Provides exhaust air capability to prevent pressurization of tight buildings.

- Actuator motor – 24 volt, power open, spring return with built-in torque-limiting switch.

COMMERCIAL ROOM VENTILATOR SEQUENCE OF OPERATION

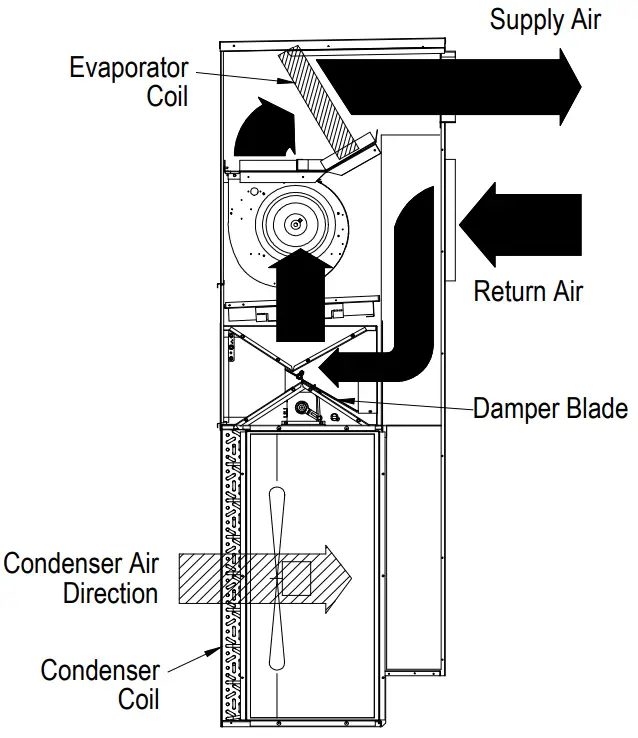

On a call for blower operation, CRV opens to a position as set by #1 Potentiometer. See Figure 7.NOTE: These sequence descriptions do not apply if a CO2 controller is used. The CRV will control according to observed CO2 levels in the conditioned space. Refer to information on Pages 7.

FIGURE 7CALL FOR VENTILATION WITH OR WITHOUT COMPRESSOR OPERATION

MIS-2829 A

MIS-2829 A

A call for 1st stage cooling or heating cycles the compressor, and the dampers reposition to the Potentiometer #2 setpoint. On loss of blower operation, CRV closes fully. See Figure 8.

FIGURE 8CALL FOR COMPRESSOR OR FAN ONLY WITH VENTILATION OFF

MIS-2835 A

Manual 2100-450M

References

[xyz-ips snippet=”download-snippet”]