Tag: ULINE

-

ULINE H-1903 Heavy Duty Glue Gun User Manual

H-1903 HEAVY-DUTY GLUE GUN 1-800-295-5510 – uline.com OPERATION Fasten output control adjuster. Plug in to a 110 volt outlet. Insert the glue stick into the back of the gun. Pull trigger several times until glue is set firmly into the inlet tube. Turn-ON/OFF switch on. Adjust the temperature knob to the desired temperature. Allow 3…

-

ULINE H-800, H-1037 Better Pack Electronic 555eS Kraft Tape Dispenser Installation Guide

H-800, H-1037BETTER PACK ELECTRONIC 555eSKRAFT TAPE DISPENSER 1-800-295-5510 – uline.com EXTERNAL VIEW EXTERNAL VIEW PARTS LIST # DESCRIPTION QTY. ULINE PART NO. MFG. PART NO. 1 Heater Assembly 1 H-800H E555-007-01 2 Main Logic Board Assembly (For H-1037) 1 H-800-BOARD E555-001-01 2 Main Logic Board Assembly (For H-800) 1 H-800MBA E555-002-01 2 Main Logic Board…

-

ULINE H-1554U-10 12 Step Rolling Safety Ladder 10″ Deep Top Step Installation Guide

H-1554U-10 12 STEP ROLLING SAFETY LADDER10″ DEEP TOP STEP 1-800-295-5510 – uline.com PARTS LISTED IN RED ARE EXCLUSIVE TO LADDERS SOLD IN CALIFORNIA. # DESCRIPTION QTY. ULINE PART NO. MFG. PART NO. 1 Stile 1 —————————– AS2052 2 Handrail Right 1 H-1554-RTHRL SU1747 3 Handrail Left 1 H-1554-LTHRL SU1746 4 No. 3 Bar 2 H-843-4…

-

ULINE Tightener Cutter H-348 Instructions

ULINE Tightener Cutter H-348 Use in combination with poly strapping and buckles only. Fits strapping widths 3/8, 1/2 and 5/8″ INSTRUCTIONS APPLY TENSION TO POLY STRAPPING Thread the poly strapping through both tightener grips and squeeze the handles to grip strapping. (See Figure 1) Pull the Tightener/Cutter until poly strapping is tensioned as needed. If…

-

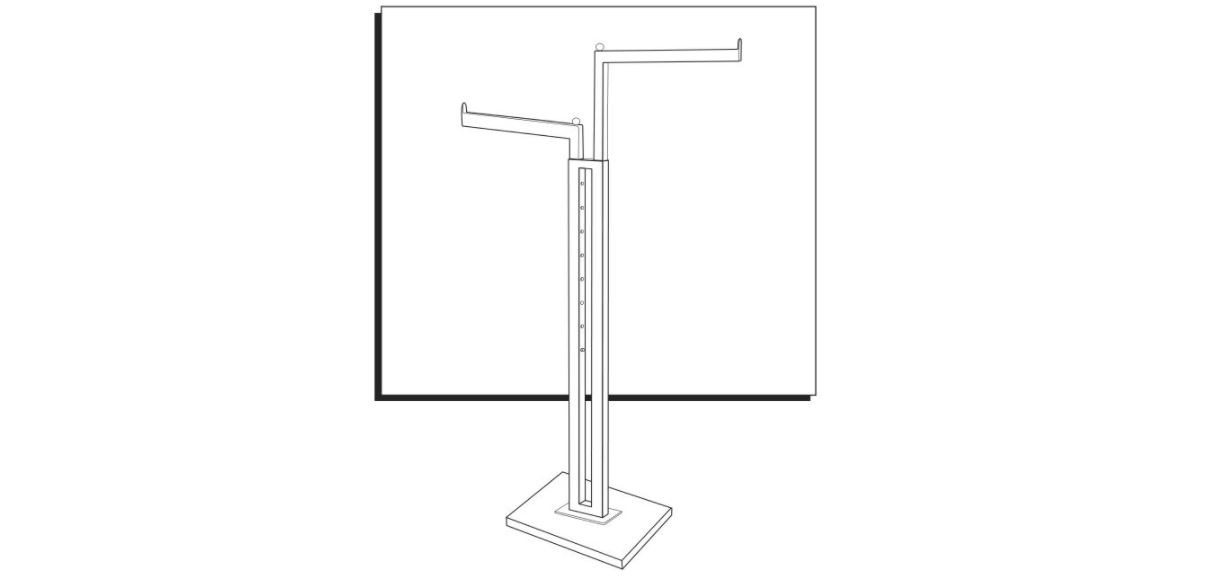

ULINE 2 Way Straight Arm Clothes Rack Instructions

ULINE 2 Way Straight Arm Clothes Rack Instructions PARTS LIST ASSEMBLY 800-295-5510 uline.mx [xyz-ips snippet=”download-snippet”]

-

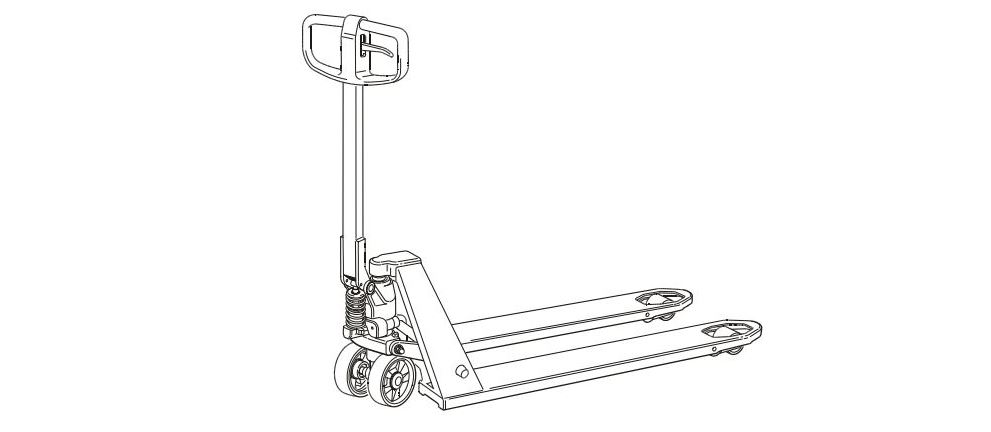

ULINE BT Pallet Truck Instructions

ULINE BT Pallet Truck Instructions IMPORTANT! Read this manual thoroughly and familiarize yourself with ALL controls and operating features. Keep this manual for future reference andmaintenance. OPERATIONS NOTE: Always wear safety shoes when working with the truck. NOTE: Always wear protective glasses when assembling or dismantling the truck to avoid personal injury. NOTE: The truck…

-

ULINE Round Clothes Rack Instructions

ULINE Round Clothes Rack Instructions PARTS LIST ASSEMBLY 1-800-295-5510uline.ca [xyz-ips snippet=”download-snippet”]

-

ULINE 60″ Frame Extension for Magliner Aluminum Hand Trucks H-3377 Instructions

ULINE 60″ Frame Extension for Magliner Aluminum Hand Trucks H-3377 TOOLS NEEDED #3 Phillips Screwdriver 7/16″ Combination Wrench Socket Wrench PARTS REF. QTY. DESCRIPTION 1 1 Frame Extension Bolts and locknuts required for assembly are included with hand truck hardware. ASSEMBLY Remove two 1/4″ – pan head bolts and two 1/4″ – locknuts from either…

-

ULINE Battery Operated Lift Table Instructions

ULINE Battery Operated Lift Table TECHNICAL INFORMATION SPECIFICATIONS H-3768 Weight Capacity 1,650 lbs. Max. Table Height 38 3⁄4″ Min. Table Height 16 3⁄4″ Table/Platform Size 39 1⁄4 x 20 x 2″ Caster Wheel Dimensions 6 x 2″ Overall Length 53″ Height Of Handle From The Ground 37″ Lift Range 22″ Lifting Cycle (Fully Charged) 100…

-

ULINE Spring-Loaded Pallet Positioner Instructions

ULINE Spring-Loaded Pallet Positioner TECHNICAL DATA SAFETY SAFETYMachine should be installed, operated and maintained by trained and/or qualified personnel only.LABELINGMachine has labeling to indicate potential hazards it may pose when operating and/or maintaining. All labels must be legible. If any label is missing, damaged or otherwise illegible, contact the manufacturer for replacement labels. SIGNAL…